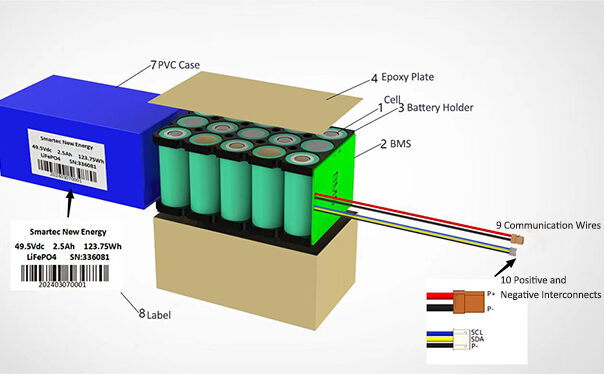

In the realm of modern technology, battery packs serve as the beating heart of many devices, from electric vehicles to portable electronics. Each component within a battery pack plays a critical role in its overall performance and safety. Let’s delve into the key components that make up a battery pack, including battery cells, Battery Management Systems (BMS), epoxy boards, brackets, custom labels, communication wires, and outer casings or PVC wraps.

Battery Cells

Battery cells lie at the core of any battery pack and are responsible for storing and delivering electrical energy. Common cell types include lithium-ion cells, lithium-iron phosphate cells, and more. The quality and performance of these cells directly impact the battery pack’s capacity, lifespan, and safety.

Battery Management System (BMS)

The Battery Management System (BMS) acts as the “brain” of the battery pack. It monitors and manages the state of individual cells. The BMS balances cell voltages, and prevents overcharging, over-discharging, and overheating, ensuring the safe and efficient operation of the battery pack.

Epoxy Plates

Epoxy plates serve as insulating materials, securing and protecting battery cells and other electronic components. They possess excellent heat resistance and mechanical strength, effectively preventing short circuits and physical damage.

Battery Holders

Battery holders are used to secure battery cells and other components within the pack. They maintain stability during use and are typically made of plastic or metal. Design considerations include heat dissipation and space utilization.

Custom Labels

Custom labels help identify the battery pack’s specifications, model, and production information. Beyond traceability and management, customized labels enhance brand image and professionalism.

Communication Wires

Communication wires connect the BMS to external devices, enabling data transmission and control. Through these wires, users can monitor real-time battery pack status, perform remote management, and conduct maintenance.

Positive and Negative Interconnects

The positive and negative interconnects form the current path within the battery pack, transferring energy to external devices. These wires must exhibit excellent conductivity and durability to ensure efficient battery operation.

Battery Case or PVC Wrap

The “battery case”or “PVC wrap” shields internal components from external environmental factors. Whether made of metal or plastic, the case provides waterproofing, dust protection, and impact resistance.